Custom Manufacturing ERP Software Development for Cummins

Overview

About Cummins

Cummins is a global leader in power technology, with more than 100 years of innovation and a commitment to building a sustainable future. With $19.8 billion in revenue and recognition as one of Newsweek’s Most Responsible Companies (2021), Cummins develops and supports a wide range of engines, components, and power solutions across industries.

Their Challenge

Cummins Pacific, a regional branch of Cummins, focused on service and distribution, needed a more efficient way to manage the complex workflows involved in large-scale equipment projects. The off-the-shelf ERP software options on the market weren’t flexible enough to fit their specific quoting, scheduling, and support needs. They needed a custom solution that could adapt to their manufacturing processes, integrate with their existing systems, and streamline project management from quoting through final delivery and ongoing service.

Our Solution

A custom manufacturing Enterprise Resource Planning (ERP) software was the ideal business solution for Cummins Pacific because of their unique trade and the information they need to keep on hand.

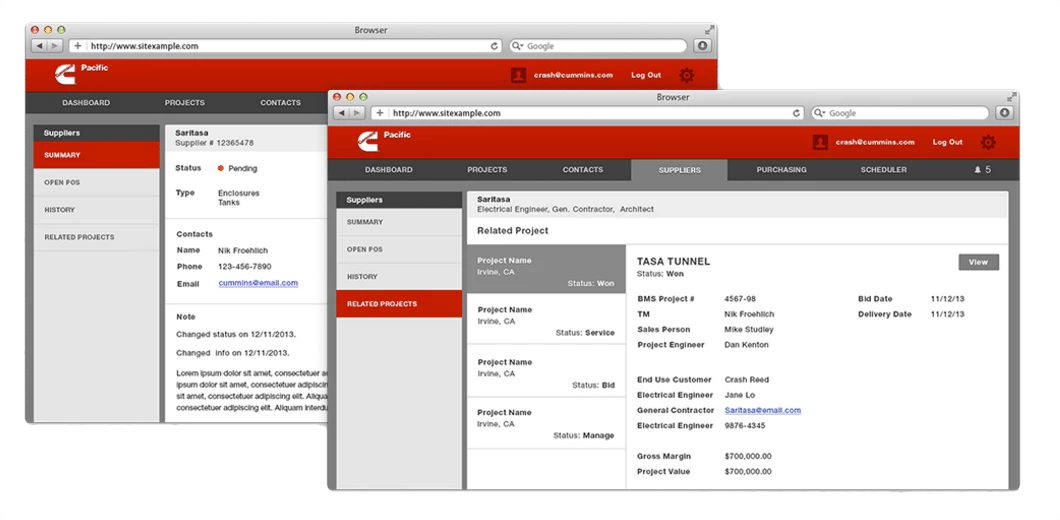

To meet Cummins Pacific’s needs, Saritasa developed a fully customized manufacturing ERP software platform tailored to the unique requirements of their operations. The web-based system supports multiple facets of their business, including sales, quoting, project management, scheduling, change orders, supply chain, and customer support. We also integrated the platform with their legacy ERP system to ensure continuity across departments.

Our Approach

What Saritasa Did

Manufacturing ERP Software Development

At the core of the project was a robust manufacturing ERP software platform designed specifically for Cummins Pacific’s workflows. Built on Linux and Apache with Oracle 11 and PHP 5.5, the system is accessible on desktops, laptops, and tablets across all operating systems. It provides a central hub to manage data across departments, helping Cummins reduce duplication, manual errors, and delays across their internal processes.

Customer Support Tools

The system supports project lifecycle management, from initial concept to completion, as well as ongoing maintenance and customer service. Having a centralized platform improves accountability and gives customer-facing teams real-time access to critical project data.

Advanced Quoting Tools

Our team developed quoting tools that allow users to generate, send, verify, and clone client quotes quickly and accurately. These capabilities are essential for complex equipment configurations and help Cummins maintain speed and accuracy across thousands of quotes annually.

Change Order Management

Projects change frequently, so we enabled granular change tracking and custom workflows for approvals. The change order management feature helps teams understand what was changed, why, and by whom, improving transparency and audit readiness.

Resources & Schedule Management

Manufacturing projects rely on efficient resource planning. The platform includes scheduling tools that allow administrators to view and assign workers across multiple projects. This visibility into resource allocation helps Cummins maximize utilization across a limited pool of specialized technicians.

Materials and Supply Chain Management

We built supply chain tools that track material usage and notify admins when reordering is necessary. These features are especially important for manufacturing ERP software, where production can be delayed by missing components. Our system ensures purchasing stays one step ahead of production needs.

Sales Synchronization

The ERP platform includes dashboards for sales tracking, forecasting, and reporting. Managers can monitor sales ratios, identify trends, and make informed decisions about inventory and staffing.

Legacy ERP System Integration

Saritasa integrated the new platform with Cummins’ legacy ERP to support existing functions such as purchasing, appointment scheduling, and maintenance management. This seamless integration preserves existing workflows while enhancing usability and functionality.